Introduction

In the fast-paced world of technology, Solid State Drives (SSDs) have taken center stage in the revolution of data storage, surpassing traditional Hard Disk Drives (HDDs) with their unparalleled speed and reliability. Yet, the journey to manufacturing SSDs is not without its economic challenges and considerations. This comprehensive analysis aims to shed light on these pivotal factors.

The SSD Revolution: Transforming Data Storage

SSDs signify a groundbreaking advancement in the storage industry, offering enhanced durability and performance. The elimination of mechanical components not only reduces the likelihood of failure but also ensures faster access to data than is possible with HDDs.

Key Economic Factors Influencing SSD Production

A Closer Look at Material Costs in SSD Production

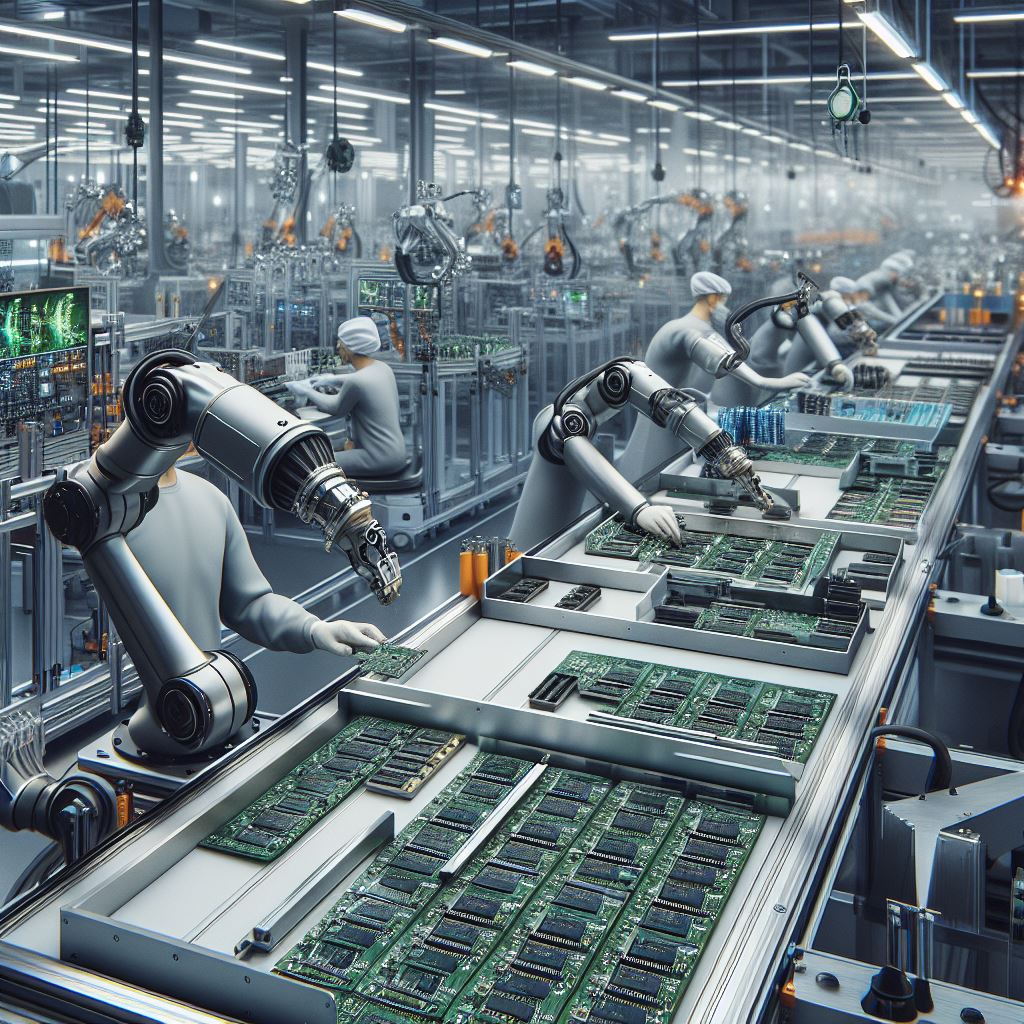

The production process of SSDs is heavily reliant on the sourcing and processing of key raw materials, notably NAND Flash Memory and Controller Chips, which are fundamental to SSD technology. These components significantly affect the cost of production and, consequently, the retail price. A comprehensive understanding of these expenses involves examining both the core materials and broader market factors.

- NAND Flash Memory: At the core of SSD functionality, the price of NAND flash memory is swayed by the global supply chain dynamics, the demand for silicon, and technological innovations that enhance storage efficiency. The fluctuating silicon prices, driven by the semiconductor demand, underscore the strategic procurement strategies necessary for SSD manufacturers to control costs effectively.

- Controller Chips: These chips, which orchestrate data management within SSDs, are crucial for ensuring speed and reliability. The complexity of these components, along with the costs associated with their sophisticated manufacturing and programming, significantly influences the overall production costs. With technological progression, these chips become more advanced and expensive to produce.

Secondary Components and Market Influences:

- Printed Circuit Boards (PCBs): PCBs provide the structural basis for component mounting and connectivity within SSDs. Their cost is affected by the complexity of the design and the prices of raw materials like copper.

- DRAM Cache: To boost performance, some SSDs incorporate a DRAM cache. The cost of DRAM, similar to NAND flash, fluctuates with the semiconductor market trends.

- Casings and Connectors: The durability and efficiency of SSDs are partly due to their metal and high-grade plastic enclosures and connectors, adding to the material costs.

Market Dynamics:

- Technological Breakthroughs: Innovations in storage technology may reduce costs for existing components but also necessitate newer, pricier materials or manufacturing methods.

- Supply Chain Fluctuations: Global events can disrupt supply chains, escalating raw material costs.

- Regulatory Changes: Stricter safety and environmental regulations may increase production expenses by requiring more costly, sustainable materials and processes.

Navigating these complexities is essential for SSD manufacturers to predict cost trends, make strategic decisions, and enhance production efficiency and affordability. This holistic approach to managing raw material costs is crucial for competitive pricing and fostering the continued market growth of SSDs.

Economic Aspects Beyond Materials

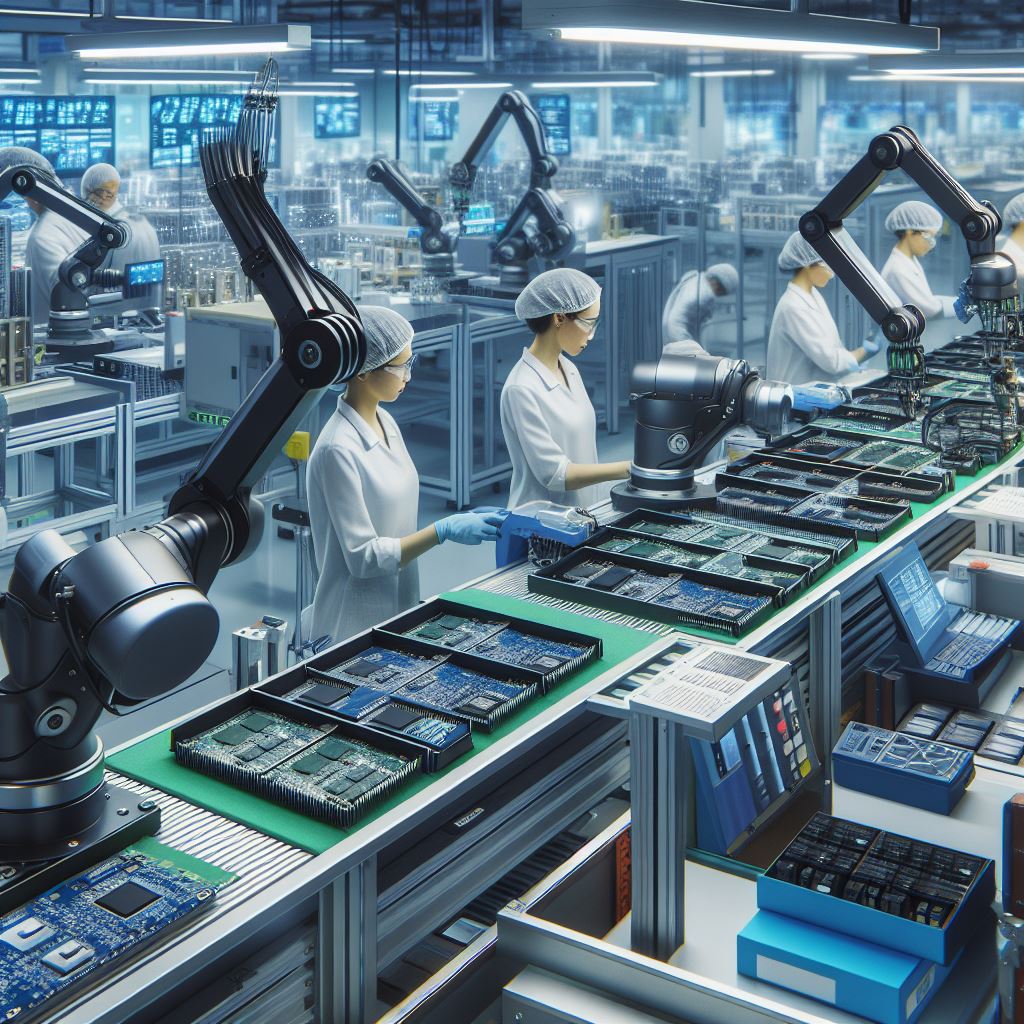

- Labor Costs: The expertise required for the design, development, and assembly of SSDs is a significant economic factor. Regions with more affordable skilled labor can provide a competitive advantage.

- R&D Investments: Pioneering SSD technology requires hefty R&D investments. Balancing these costs is essential for staying competitive.

Market and Technological Dynamics

- Demand and Supply Equilibrium: The SSD market is influenced by the balance between demand and supply, affecting both production strategies and pricing.

- Competition: The competitive drive encourages manufacturers to innovate and manage costs efficiently.

- Technological Advancements: Progress in technology not only optimizes production costs but also widens the SSD market through new applications and increased demand.

Regulatory and Global Economic Context

- E-waste and Compliance: Regulations around electronic waste disposal and manufacturing standards impact production costs and practices.

- Global Economy: Currency fluctuations and trade policies can significantly affect the cost dynamics and global competitiveness of SSD manufacturing.

Conclusion

The SSD manufacturing landscape is intricately shaped by a myriad of economic factors. For stakeholders in the tech sector, understanding these dynamics is crucial for navigating the SSD market’s complexities and seizing opportunities. As the industry progresses, staying informed and adaptable remains vital for success.

FAQs

- What drives the cost of SSD production the most?

- How do technological advancements influence SSD manufacturing expenses?

- Do regulations affect the SSD industry?

- What role does the international economy play in SSD production?

- Which emerging trends could impact the economics of SSD production?

Leave a Reply